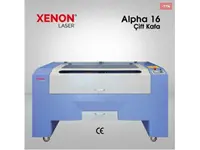

Advertising Laser Cutting Machine Popular Products

Laser cutting machines offer great convenience for making detailed, fast, and fine cuts. These machines allow cutting for both work and hobby purposes on different surfaces, completing your needs in the fastest time while producing cuts with high qualities.

What is Laser Cutting?

Laser cutting is a cutting process used to obtain suitable parts for hobbies or various industries. It is preferred for cutting materials such as iron, bimetal, wood, stainless steel, and metal, commonly used for industrial purposes but also chosen for school, hobby shops, or similar purposes. Laser cutting processes are usually performed by directing the output of high-power laser through optics. Laser optics and materials produced with CNC use to direct the laser beam are used in the cutting technique. The machines used to cut materials operate by loading the CNC or G code of the pattern to be cut on the material. The focused laser beam is directed to the material to be cut, and then fine cutting processes are performed using methods such as melting, burning, vaporizing, or gas blowing. Laser cutting machine prices vary according to these cutting features. Also, industrial-type laser cutters can be used to cut not only flat sheet materials but also profile and pipe materials.

How is Laser Cutting Done?

Different cutting methods are preferred to make laser cuts. Although machines have different features depending on the plate to be cut, the working methods are the same. Generating laser beams involves stimulating electrical resonances in a closed chamber. The shining material is turned into a light flow along with the excitation, and to escape, it is reflected by mirrors to obtain sufficient energy ratio. The reflected mirrors consistently reflect the consistent light in the form of fiber optics. Thus, a high-temperature laser beam is sent to the focused point, and thanks to this beam, patterns stored in the machine's memory can be cut on the plate. All these processes are done in very short times, and thus cutting processes also reach results in a short time.

What are the Advantages of Laser Cutting?

Paralleled beams of light consistently reflected in laser cutting sources are usually between 1.5 - 2 mm. This beam, which usually creates an intense laser beam through lenses or mirrors under normal conditions, focuses on very small points and intensifies. It is important to achieve the smoothest possible surface during contour cutting, so it is important for the laser machine to concentrate and focus as well as possible. Laser cutting on mechanical cuts increases the availability and compatibility of the workpiece. Due to its high precision adjustments and the small area affected by heat in laser systems, the possibility of damage to the cut material is very low. Also, cutting metals with laser shows much more precise properties compared to plasma cutting. They also have advantages in terms of using less energy while cutting the sheet. In addition, most industrial lasers used cannot cut thicker materials than plasma cutting can cut. New type laser machines working at high power levels also help in making precise cutting operations on thicker materials than plasma can cut.

In addition to all these, laser cutting has great benefits in other areas as well. The absence of mold costs in part productions offers significant advantages to cutting processes. Also, regardless of the plate structure, all kinds of writings, emblems, or images can be easily processed and cut on the plate. Laser cutting, offering time savings because of its speed, can create suitable results even in very intense work pace. Economically, it facilitates cutting parts without any damage, providing convenience. With their high processing speeds, they allow more work to be done, causing an increase in the volume of work. One of the biggest advantages is that laser cutting creates a safe cutting opportunity without damaging the plate used.

What are the Models of Laser Cutting Machines?

Laser cutting machines differ according to the plate to be cut. It is important to choose the right models according to the area where cutting will be done to achieve the desired results.

Wood Laser Cutting Machines

Wood laser cutting machines are machines that allow cutting only on wood surfaces. With these machines, which are very important for wood processing operations, you can perform your hobby or industrial operations. Wood models that allow you to choose laser power, processing surface, and other features according to your needs make even the most delicate operations easily achievable. These machines can also be used as hobby laser cutting machines. Since wood is considered as the basic board for hobby materials, wood laser machines will provide great benefits in providing the materials for hobby purposes.

CNC Laser Cutting Machines

CNC laser cutting machine is the laser machine that allows cutting with the CNC logic. Laser beams are formed using special gases and allow very short time operations such as 2D cutting, engraving, and drilling. The desired shapes are prepared in the computer environment, and these files are transferred from the computer to the machine to start the cutting processes. Because cutting is done with laser beam, the desired cuts are achieved perfectly. It meets the needs accurately for both hobby and industrial use due to its precise cutting.

Laser Cutting Models for Home Use

With plexiglass laser cutting machine models for home use, you can easily carry out your cutting operations at home. If you like to create new things at home or want to prepare products for sale at home, the plexiglass laser cutting machine will meet your needs accurately. Keeping in mind the wide range of applications, the prices of wood laser cutting machines are also considered. Especially the widespread preference for wooden products in homes highlights the laser machines that allow cutting as wood.

With a home laser cutting machine, you can turn your home into both a hobby room and a small business. These specially constructed models for use in homes allow you to work on different plates safely. With these models, also known as mini laser cutting machines, you can make your delicate cuts on different plates in the best way. You can also choose metal laser cutting machine models to work on metal as well, not just on plexiglass or wood.

Laser Cutting Machine Prices

| Laser Machine Model | Price |

|---|---|

| 60*40 Cm Working Area Single Head Laser Cutting Machine | 21,000 TL |

| Laser Cutting Machine 600x900 | $6,500 |

| Large Camera Conveyor Belt System Laser Cutting Machine | $15,000 |

| 100*160 Cm Working Area Double Head Laser Cutting Machine | $5,900 |

| Fiber Laser Cutting Machine 6,500-1,500 Mm | $50,000 |

| 20 W Fiber Marking Machine | $4,750 |

| 130*90 Cm Working Area Projector Laser Cutting Machine | $7,500 |

| 60*40 Cm Working Area Laser Cutting Machine | 21,000 TL |

| 100*160 Cm Working Area Double Head Laser Cutting Machine | $5,900 |

There are different prices for all laser cutting machines, including wood laser cutting machine or hobby wood laser cutting machine prices, depending on their features and powers. Prices are determined according to the features and laser powers of the devices. However, with a wide range of options available, you can find the most suitable among different laser cutting models.