120/ 160 Kg Conical Twin Screw Plastic Pvc Profile Extruder 1

Karakuş Machinery 120/ 160 Kg Conical Twin Screw Plastic Pvc Profile Extruder

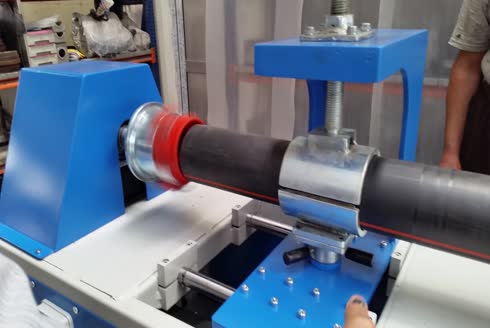

Plastic PVC profile machine are extrusion lines that allow the production of PVC profiles in desired sizes and lengths. These machines are used in the production of many products such as window profiles, PVC paneling, door and wardrobe paneling, cornices, glass beads, sills, etc. The production line generally consists of main machine extruder, profile die, vacuum calibration table, haul-off unit, profile saw, and flip table units.

Extruders are classified as single screw and conical twin screw. Single screw models are usually produced in Ø50, Ø70, Ø90 diameters; while conical twin screw models are offered in Ø50, Ø67, Ø75, Ø90, and Ø110 options. In the working principle, the raw material is melted and formed into a mold through the screw and barrel system. The profile that exits in a molten state is cooled on the vacuum calibration table to obtain the desired dimensions. Then, the haul-off unit moves the profile in a regular manner and sends it to the saw unit. The cutting process is done according to the dimensions of the profile, and the product is stacked at the final stage ready for use.

Plastic PVC profile machines offer indispensable production solutions in the industry by providing high efficiency and accuracy.

Karakuş Machinery 120/ 160 Kg Conical Twin Screw Plastic Pvc Profile Extruder Technical Specifications:

MODEL |

65 /132 |

80/156 |

92/188 |

Screw Length / LD |

1440 |

1843 |

2500 |

Max. Back Pressure |

350 KN |

400 KN |

450 KN |

Motor Power |

37 KW |

55 KW |

75 KW |

Reducer Ratio |

1/15 |

1/15 |

1/15 |

Screw Revolution |

50 rpm |

50 rpm |

50 rpm |

Cylinder Cooling System |

5 |

6 |

6 |

Installed Electric Power |

50 KW |

70 KW |

85 KW |

Capacity |

120/ 160 KG |

200 / 250 KG |

300 / 350 KG |

Sıradaki