12,500-13,500 cups/hour 10-Cup Water Thermoforming Machine 2

10-cavity mold machine, with a production capacity of 13,500 cups per hour, can produce 3 different cup sizes such as 150 ml, 200 ml, and 250 ml with the same mold using Bottom Height Adjustment.

General Structure:

|

A. Machine Length |

B. Machine Width |

C. Machine Height |

|

5045 mm |

1045 mm |

2050 mm |

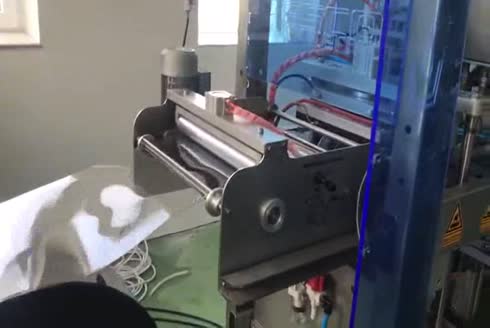

Machine process sequence:

-

100 cm diameter. Lower coil feeding unit

-

4-step heating unit

-

Air Pressure Control and Circuit Breaker System

-

Plexiglass doors

-

PNEUMATIC Moving PUNCH unit

-

PNEUMATIC Moving SHEAR System Shaping Station

-

Air Shaft with Upper film holder and Heated tensioning system

-

Photoelectric Cell System

-

PNEUMATIC Moving SHEAR System Gluing Station

-

Upper Pressure Piston reinforced Gluing Unit

-

SERVO Moving & screw Pulling unit

-

Reducer driven Crank push arm Cutting unit

-

Lubrication entries in column shaft and bearings

-

Upper film waste winding unit

-

Cabin interior lighting

-

Lower film waste Cutting unit

-

Conveyor inside Cutting

-

Pneumatic valves and Cylinders FESTO -SMC -MIDMAN -PNÖMAX.

-

PLC system OMRON-SIEMENS-VEICHI.

-

Control Screen will be with 10” COLOUR TOUCHSCREEN.

-

Servo and Driver Equipment (OMRON-VEICHI)

-

All contactors and motor protections to be used will be Siemens or Telemecanique.

-

Stainless tank for Air Balance inside the machine is standard on the machine.

-

7075 Aluminum and 304 & 316 L Quality stainless steel have been used on the machine.

Water Cup Machine Energy Consumption:

Electric: 15 KW/hour at Initial Start, standard operation 7.5 KW/hour

Air: 6—8 Bar. 2.5 m³ / min