200 Kg Vertical PVC Mixer – Heated Raw Material Mixing Machine 1

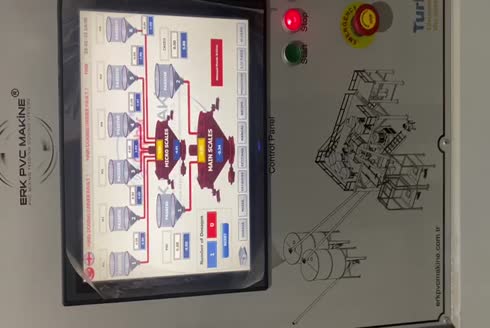

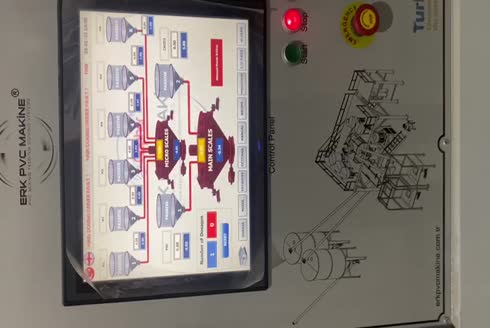

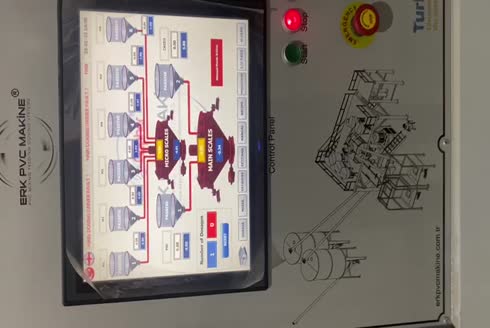

200 Kg Vertical PVC Mixer – Heated Raw Material Mixing Machine (EPM‑V200 FV/SS)

Erk PVC Makine

Product Description

The mixing stage is the first and most critical step in the PVC production process and directly impacts product quality. For a homogeneous and efficient blend, the right mixer technology must be used. ERK PVC Makine, with its extensive industry experience, is among the leading companies in the PVC mixing field, offering high-performance solutions to its customers.

The new generation GM-TURBO Mixer Series ensures perfect homogeneity and short cycle times in both soft and rigid PVC formulations. The heart of the mixing process—the impeller design—has been optimized based on ERK PVC Makine’s field experience, aiming for maximum efficiency and minimum error during production.

.jpg)

.jpg)

.jpg)

Application Areas

- PVC Door and Window Profiles

- PVC Curtain Rails

- PVC Cable Ducts and Cables

- Wastewater and Clean Water Pipes

- Irrigation Hoses

- Waterproofing Products

- PVC Flooring

- PVC Foil and Tarpaulin

- Wood-Plastic Composite Panels (WPC)

- Metallic Powder Coating (Bonding Mixer) Production

Technical Specifications

| Mixer Model | EPM-V200 FV / SS |

| Production Capacity (Batch/Hour) | 3–4 |

| Total PVC + Additives Capacity (kg) | 200 |

| Heater Mixer Volume (L) | 540 |

| Heater Mixer Motor Power (kW) | 90 |

| Cooler Mixer Volume (L) | 850 |

| Cooler Mixer Motor Power (kW) | 11 |

Alternative Capacity Options

| Mixer Model | 100 Kg | 150 Kg | 200 Kg |

|---|---|---|---|

| Production Capacity (Batch/Hour) | 3–4 | 3–4 | 3–4 |

| Heater Volume (L) | 300 | 450 | 540 |

| Heater Motor Power (kW) | 45 | 75 | 90 |

| Cooler Volume (L) | 520 | 700 | 850 |

| Cooler Motor Power (kW) | 5.5 | 7.5 | 11 |

200 Kg Vertical PVC Mixer – Industrial Heated Mixing Solution

The 200 Kg Vertical PVC Mixer is a heated raw material mixing machine designed for high-volume production facilities. It ensures maximum homogeneity, energy savings, and stable performance in PVC mixing processes. Among plastic raw material mixers, this model stands out for its high efficiency, durable structure, and low maintenance cost.

EPM-V200 FV/SS, developed by ERK PVC Makine, enables smooth blending of both soft and rigid formulations. Thanks to its Industry 4.0-compatible automation system, it integrates easily into production lines and accelerates manufacturing processes with its user-friendly design. It is a reliable solution for high-capacity PVC production lines.