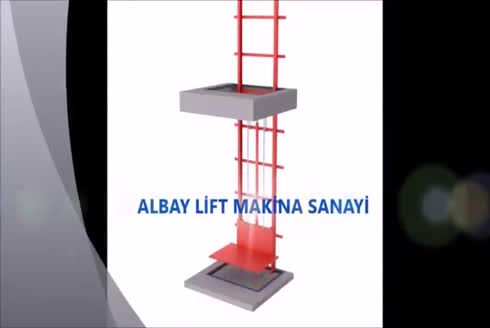

3 Ton 8 Meter Double Piston Hydraulic Cargo Elevator

Hydraulic Freight Elevator

- Single Piston and Double Piston options

- Freight Elevator, Disabled Elevator, and Vehicle Lifting Elevator options

- Capacity, lifting height, and platform options according to your request

- Models with or without a cabin

- Inverter (Dual Speed) System Option

Hydraulic freight elevators provide significant convenience in every area of our business life. They save labor and provide great ease in your work. They not only carry your load but also make it easier to transport it safely.

It is essential to transport your expensive products securely and without taking risks. In rope-based or other lifting systems, there is always a risk of rope breakage. For this reason, recent work safety laws mandate that “ropes must be changed every 6 months.” Similarly, “periodic maintenance companies” also base their operations on this rule. However, there is no such restriction in freight elevators.

Hydraulic freight elevators not only carry your load safely but also amortize themselves in the shortest time possible, with maximum efficiency and minimum costs.

The hydraulic freight elevator is your professional partner that lightens your load.

HYDRAULIC SYSTEM PISTON CHAIN LIFT ELEVATORS

Our freight elevators are divided into two main groups: conveyor mechanism-based freight elevators and fixed chassis-based freight elevators.

Conveyor-based freight elevators are designed as PLC module-controlled in fully automated production lines. The products to be transported by the conveyor system come to the front of the elevator. If the elevator is in use, other products remain on standby, and the conveyor system automatically stops. Then, the conveyor system inside the freight elevator takes the product and carries it to the desired floor, continuing the shipment.

Freight elevators, other than conveyor systems, are also designed by us with iron chassis components. After our engineering team takes measurements and prepares the project, we manufacture them in any size and floor distance.

Lift Systems: These are typically preferred in areas with elevation differences. They are usually equipped with roller components. After the load arrives on the lift, the lift moves up or down to the level where the product will be transferred, and then the drive rollers operate to transport the product.

Product Documents

CE Certificate

Quality Certificate

TS EN 13001-1:2015

EU 13001 Quality Certificate

Warranty Certificate

Load Certificate