Automatic Liquid Filling Machine 2

Automatic Liquid Filling Machine

Offering high speed, accuracy, and hygiene on production lines, the automatic liquid filling machine enables liquid products to be filled into bottles, jars, or similar containers in a fully measured and leak-proof manner. Widely used in the food, cosmetic, chemical, pharmaceutical, and cleaning product industries, it is suitable for working with liquids of different viscosities.

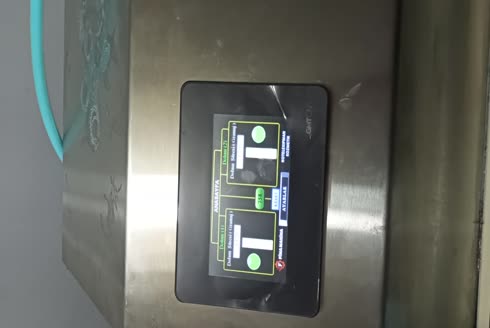

With advanced control system and adjustable filling parameters, it provides ease of use to the operator while minimizing production losses. Its stainless steel body and hygienic design comply with GMP and food safety standards.

Main Features:

-

Automatic product feeding and container placement system

-

Adjustable filling volume and speed control

-

Compatible with different types of liquids (water, syrup, oil, disinfectant, etc.)

-

Easy to use with a touchscreen control panel

-

Stainless steel body (AISI 304 or optional AISI 316)

-

Easy cleaning and maintenance

-

Optional multi-nozzle filling head option

-

Production compliant with CE standards

Advantages:

-

High filling accuracy

-

Reduction in labor costs

-

Structured for mass production

-

Hygienic and reliable filling process

To package your products in a quality, fast, and hygienic manner, our automatic liquid filling machine is an ideal solution. For models and technical support tailored to your production capacity, please contact us.

The automatic liquid filling machine is designed to fill a wide range of products. Products to be filled are generally classified based on the viscosity of the liquid. Below are the main product groups that the automatic liquid filling machine can fill:

💧 Low Viscosity (Watery) Products:

-

Water

-

Cologne

-

Vinegar

-

Alcohol-based solutions

-

Disinfectants

-

Fruit juice

-

Energy drinks

-

Milk

🧴 Medium Viscosity Products:

-

Liquid soap

-

Shampoo

-

Dishwasher detergent

-

Hand sanitizers (including gel formulations)

-

Tonics and lotions

-

Herbal extracts

-

Liquid fertilizers

High Viscosity (Thick) Products:

-

Olive oil and other liquid oils

-

Syrup

-

Honey (may require special pump)

-

Thick sauces (ketchup, mayonnaise, etc.)

-

Engine oil

-

Glycerin

-

Cosmetic products in gel form

Industrial and Chemical Products:

-

Cleaning agents (bleach, surface cleaner, etc.)

-

Antifreeze

-

Paint additives

-

Chemical solutions

-

Agricultural pesticides

Notes:

-

Each product may require a suitable nozzle type, pump system (peristaltic, piston, vacuum, etc.), and filling adjustment.

-

Special modifications may be required in the machine especially for dense, foamy, or corrosive substances (such as Teflon coating, acid-resistant material, anti-foam system, etc.).