Ptw-15

- 100 cm diameter. Bottom Coil Feeding Unit

- 4-Stage Heating Unit

- Air Pressure Control and Circuit Breaker System

- Fully Protected Stations with Covers

- Flexi Glass Sliding Doors

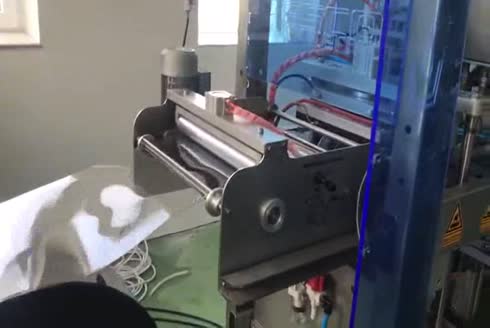

- SERVO Driven MAÇA Unit

- SERVO Driven Shaping Station

- Level Controlled Feeding Valve

- Cylindrical Water Filling Tank

- PLC Time Controlled Water Filling Valves

- Air Shaft with Top Film Holder and Heated Tensioning System

- Photoelectric Heated Tensioning System

- SERVO Driven Gluing Station

- Top Pressure Piston Reinforced Gluing Unit

- SERVO Driven & Screw Drawing Unit

- Reducer Driven Crank-Push Cutting Unit

- Lubrication System in Column Shaft and Bearings

- Top Film Scrap Winding Unit

- Bottom Film Scrap Cutting and Winding System

- Conveyor Height at Cutting Exit Adjustable According to Cup CC Size

- Pneumatic Valves and Pistons are from FESTO, SMC, MIDMAN, PNÖMAX (Japan)

- PLC System is OMRON or VEICHI (Japan)

- Control Screen will be 10” COLOUR TOUCHSCREEN

- Servo and Drive Equipment OMRON or VEICHI

- All Contactors and Motor Protection Devices are from Siemens or Telemecanique

- Stainless Steel Tank for Air Balance in the Machine is Standard

- The Machine is Made from 7075 Aluminum and 304 & 316 L Quality Stainless Steel

- Water Filling Tank has a Sight Glass

- Water Filling Tank is Cylindrical for Full Hygiene (316 L)

- The Filling Tank has a Cleaning Nozzle and Entry Connection for CIP

- The Machine's Frame is Made of Stainless Steel Profile Sheets

- Visual Alarm for All Fault Conditions

Sıradaki