CNC ROUTER WOODWORKING MACHINE 1

CNC ROUTER WOODWORKING MACHINE

The CNC Router woodworking machine is used for precise cutting, carving, and shaping of various wooden products such as furniture,decorative panels, doors, cabinets, andwooden boards.

Thanks to its computer-controlled system, it ensures high precisionand repeatability.

These machines are ideal for both mass production and custom projects.

With a user-friendly programmable interface, it is easy to operate.It works efficiently with materials such as MDF, solid wood, plywood, and acrylic.

Key Features

-

High-precision cutting and engraving capabilities

-

Automatic tool changer (optional feature)

-

Strong vacuum system for stable part holding

-

Durable body and long-lasting components

-

Compatible with CAD/CAM software

Machine Dimensions & Axis Travel

-

Overall machine size: W: 3000 mm / L: 4200 mm / H: 2300 mm

-

Axis travel: X: 2100 mm / Y: 2800 mm / Z: 1350 mm

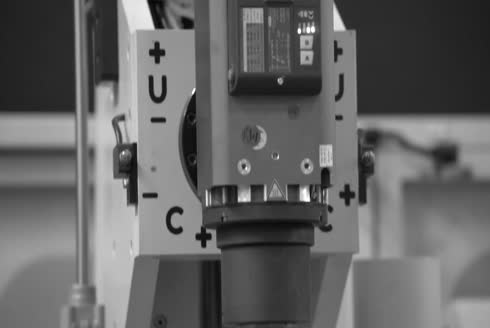

Servo Motors & Drives

-

X Axis: 1.5 kW 3000 RPM B2 DELTA Servo Motor

-

Y Axis: 0.75 kW 3000 RPM B2 DELTA Servo Motor with Brake

-

Main inverter: 11 kW DELTA VFD-F Inverter

Mechanical Structure

-

Reducer: 1/10 – 120/5 (arcmin), LIMING body

-

Table surface: COMPACT 16 mm (GENTAŞ)

-

Rack and pinion system:

-

25x25, 2-module BRL helical, hardened and ground

-

Q7 taper clamping Q7 pinion

-

-

Linear guides:

-

Y Axis: 35 mm

-

X Axis: 25 mm (STAF)

-

Automation & Control

-

Control unit: 4-axis RADONIX (PC control with Turkish interface)

-

Automatic lubrication system

-

Automatic homing function

Tool Changer & Spindle

-

Under-bridge automatic tool changer: 14-position

-

Spindle: 9 kW, 24,000 RPM HQD

-

Vacuum pump: BLK-250, 7.5 kW, 260 m²/hour, dry type

Vacuum System

-

6 vacuum zones

-

Fully automatic zone control

General Specifications

-

Positioning pistons: 6 units, 50x50-20 mm

-

Total power consumption: 27 kW

-

Working pressure: 6–8 bar air

-

Machine weight: 4000 kg

-

Warranty: 2 years