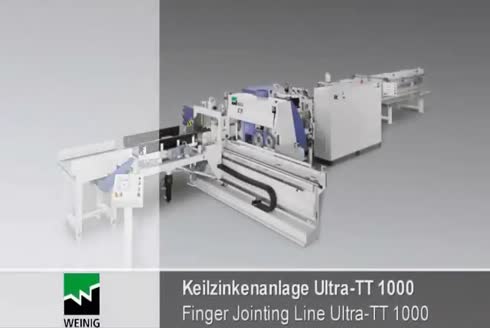

Doubletech Double-Head Finger Joint Machine

Fully Automatic Double-Head Finger Joint Machine

One of the advanced technology products of ÖZEN Machine, Doubletech is designed for high-volume wood joining operations with its fully automatic structure. Thanks to its double-headed system, it maximizes productivity and provides significant speed and efficiency in wood processing processes.

Ideal for High Volume Production

The Doubletech model is an excellent solution for facilities engaged in mass production, with a processing capacity of up to 12 m³ per hour. With its advanced automation system, maximum output is achieved with minimal human effort. It allows wood pieces to be joined end-to-end, transforming them into longer and stronger materials.

High Efficiency with Double-Headed System

The machine's double-headed design allows for the processing of two pieces simultaneously. This not only saves time but also increases the fluidity of the production process. Cutting, milling, gluing, and pressing operations are carried out fully automatically. Thus, high precision and consistency are achieved in every piece.

Fully Automatic, User-Friendly Structure

Özen Doubletech requires minimal operator intervention with its fully automatic structure. It is equipped with features such as an easy-to-use control panel, quick adjustment transitions, and production tracking. With its ergonomic design and advanced safety systems, it offers safe and efficient operation for long hours.

Technical Specifications (Basic Information)

-

Machine type: Fully automatic, double-headed

-

Processing capacity: ~12 m³/hour

-

Application: Joining wood pieces using the finger joint method

-

Process steps: Cutting, milling, gluing, pressing

-

Areas of use: Solid panel production, cutting, furniture, construction timber

-

Automatic feeding and unloading systems (optional)

(If you share detailed technical data, I can expand the technical table.)

Powerful Solution for Industrial Production

Özen Doubletech meets the needs of large-scale production businesses with its high capacity, full automation, and precise processing capability. It is a system that offers quality, speed, and durability in the wood sector, ensuring you get more than your investment back.