Full Model Bias Cutting Machine 6

Automatic Bias Cutting Machine Full Model KM 1850

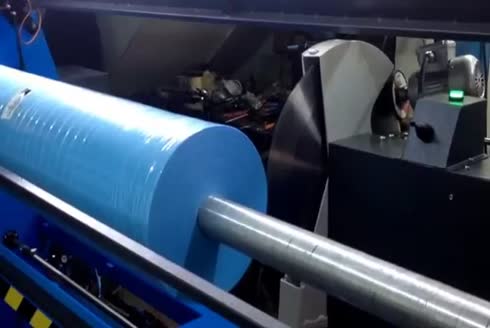

Nonwoven fabric cutting machine KM1850 (Automatic Bias Cutting Machine Full Model KM 1850)

Bias cutting machines

CAN CUT INTERFACING AND FELT

MACHINE CAPACITY:

Cutting Range: 1 mm – 2100 mm Cutting Length 2400 mm can be specially produced in the desired size

7.5 Gear reducer

Blade motor 3kw 75 body

Cutting plunge motor 12.5 NM

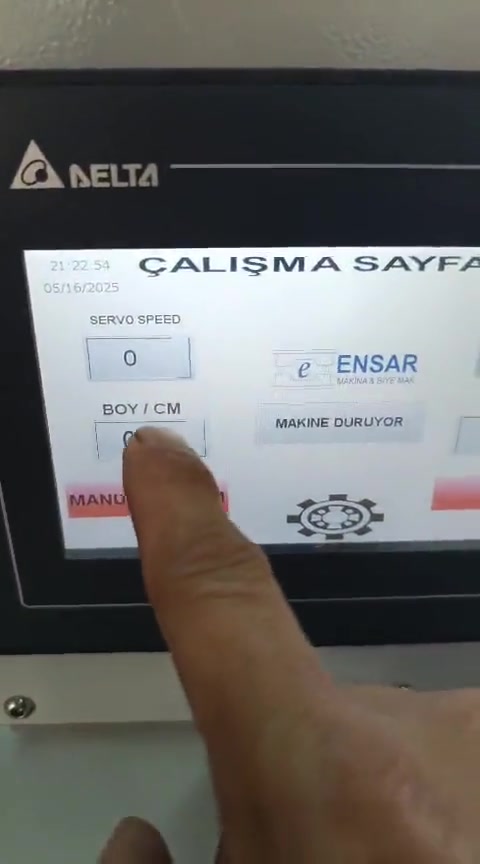

PLC screen Delta brand

Servo motor scaling 0.75KW

Shank Thickness Range: 3 inch

Max Diameter Width: 45cm rolls

Cutting Precision: +-00.1 mm

Automatic Bias Cutting (Slicing) Machine

Automatic roll attachment place pneumatic lift

FUNCTIONS:

Manual and semi-automatic use

LCD 7 inch color screen

Speed adjustment of all moving parts

Blade sharpening (quantity and time controlled)

Liquid spraying (quantity and time controlled)

Measurement and cutting quantity adjustment (5 pieces)

Motors forward and reverse rotation

Automatic reset

7.5 Gear reducer

Blade motor 3kw 75 body

Cutting plunge motor 12.5 NM

PLC screen Delta brand

Servo motor scaling 0.75KW

600 mm steel blade

NONWOVEN SYSTEM

Nonwoven fabric cutting machine

600 MM BLADE

SCALING SERVO SYSTEM MOTOR

TOUCHSCREEN 7 INCH SCREEN

CLOSED-CABIN-PROTECTION-SYSTEM

WATER and AIR COOLED

11.5 KW

35 50 75 MM ROLL SHAFT OTHER LENGTHS CAN BE MADE ON REQUEST

7 inch PLC / OPERATOR PANEL

All mechanical and electrical equipment systems on the machine are under PLC control.

There is a touch screen operator panel that is very easy to use and can control all functions on the machine .

Automatic Bias Cutting Machine Full Model KM 1850

OTHER MATTERS:

ASSEMBLY AND COMMISSIONING:

1 assembly personnel will be assigned by KANMAK MACHINE.

You must notify your assembly request at least 1 week in advance.

In domestic assemblies, intercity transportation costs belong to KANMAK MACHINE, accommodation costs and transfers between hotel - business - hotel belong to the BUYER company.

Provision of a minimum 1.5-ton capacity forklift for use at the assembly site is the responsibility of the buyer company.

During the assembly, to assist the assembly personnel;

1 mechanical / 1 electrical personnel should be assigned by the BUYER company.

Additionally, if necessary, 1 construction personnel should also be provided.

The maximum assembly time is 1 day.

If possible, an office should be allocated for the use of our assembly personnel.

Before your assembly request; the machine should be placed in the assembly area, but the packaging should not be opened. Opened packages and their contents will be excluded from the warranty.

The supply of electrical installations and materials up to the panel is the responsibility of the buyer company.

The supply of air lines and materials up to the main conditioning inlet is the responsibility of the buyer company.

The necessary construction works are the responsibility of the buyer company.

WARRANTY AND SERVICE:

During the warranty period, the need for spare parts due to manufacturing defects is free of charge. The warranty period against manufacturing defects is 12 months. This period starts from the day the machine is commissioned/test production begins. If the buyer company delays the assembly for various reasons, the warranty period can be extended up to 15 months from the date of completion of manufacturing.

The warranty of consumables is covered by their own manufacturers' warranty.

After the warranty period ends, service is provided, but the travel and accommodation costs of the requested service personnel and daily working fees, as well as the costs of materials to be used, are the responsibility of the buyer company. The working fee is determined according to the values at that time.

PACKAGING:

Partial packaging is done with cardboard, foam, and stretch film materials to prevent wear during transportation.

TRANSPORT + INSURANCE:

Transport and insurance belong to the BUYER COMPANY.

DELIVERY METHOD:

30 business days after order confirmation and advance payment. MAY BE READY, PLEASE INQUIRE

This period does not include delays that may arise from imported material inputs and natural disasters.

KANMAK ALSO MANUFACTURES CUTTING MACHINES, CLICK HERE

VISIT OUR PAGE FOR OTHER VIDEOS, CLICK HERE