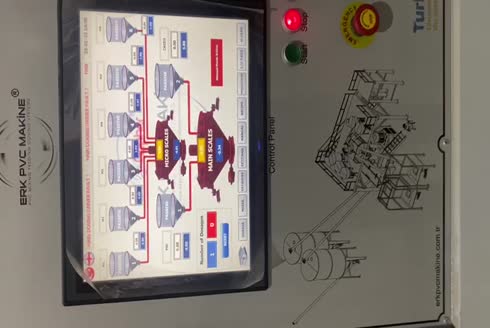

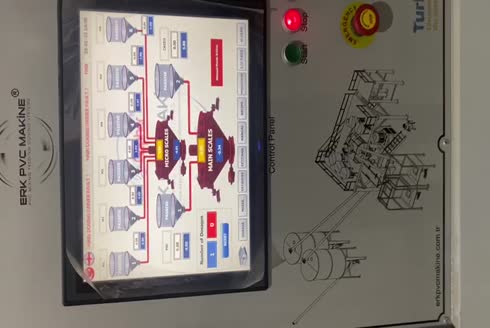

Gravimetric Automatic Powder Dosing System – PVC and Plastic Raw Material Feeding Machine 1

Gravimetric Automatic Powder Dosing System – ERK PVC Machine

General Description

ERK PVC Machine offers high precision and efficiency in PVC production with its developed automatic gravimetric powder dosing system. Thanks to its fully automatic structure, formulations are prepared without human contact and transferred flawlessly to silos or extruders, ensuring safe feeding operations.

The system measures each component of the formulation with the highest accuracy on a weight basis using gravimetric weighing technology. In this way, zero error, minimum waste, and maximum homogeneity are achieved in production.

Application Areas

- PVC Door and Window Profile Production

- PVC Pipe and Cable Systems

- WPC (Wood Composite Panel) Production

- Plastic Granule and Masterbatch Production

- Metallic Powder Coating and Chemical Mixtures

- Automatic Extruder Feeding Systems

Product Advantages

- 100% precise gravimetric weighing technology

- Hands-free production and full automation

- Recipe-based formulation management

- Homogeneous mixture and zero-error target

- Energy efficiency and minimum raw material loss

- Easy integration and Industry 4.0 compatibility

Gravimetric Powder Dosing System – Industrial Solution

The Gravimetric Powder Dosing System developed by ERK PVC Machine provides maximum efficiency to production facilities with its high-precision weighing sensors and automation-supported structure. Widely used in PVC, plastic, and chemical industries, this system is one of the most reliable options among automatic dosing and feeding solutions.