Laminating Machine kategorisinde ürün bulunamadı.

Benzer kategorideki diğer ilanlar listelenmektedir.Types and features of printing machines

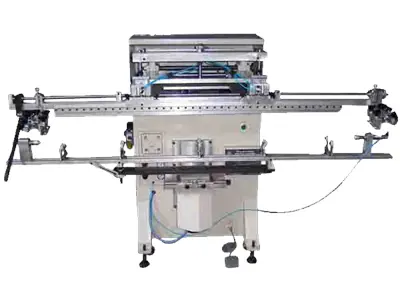

Printing machines are machines that allow us to print and reproduce on different textures such as images, advertising visuals, the printing industry, shapes, fabric, paper, leather, glass, etc. They are the basic tool of printing and are widely used in the advertising field as well. Nowadays, companies use printing machines to promote and increase sales in every business area such as small businesses. Content related to printing machines is available with the contact information details of the best printing machine companies in the sector. You can also contact the companies to choose the perfect printing machines that can meet your needs and place printing machine orders on our website. For example, if you are looking for lamination, cleaning paper, parts, and materials, you can easily find the best printing machines in the Machinery Turkey page where the leading companies in the sector are listed. There are around 1300 second-hand printing machines available for sale with over 350 sellers waiting for you. You can instantly reach hundreds of sellers with sales and rental options, brands, and models of printing machines in this category.

Offset lithography printing is often done on an aluminum printing plate, which shows the image to be printed. When the plate is inked, only this image area retains the ink. This inked image is then transferred from the plate to a rubber blanket and then to the printing surface (or offset). The process can be used to print on paper, cardboard, plastic, or other materials, but they must have a flat surface. Below is an image of a 4-color sheet-fed printing machine. At the top, there is a feeder where individual paper pages are automatically fed into the printing machine. Each tower or printing unit of the 4 colors typically prints in black first, then in cyan, magenta, and yellow. The printed stack of paper can be seen on top, below which is the monitor used by the printing operator to control the printing. There is a trend towards digital printing for the slow transition of printing promotional materials, and some packaging prints have shifted to flexography. In flexography, the content to be printed is on a relief made of rubber. This relief is inked, and the inked image is then transferred to the printing surface. The process can also be used to print on plastic, metal, cellophane, and other materials in addition to paper.

Flexo Printers are mainly used for packaging and labels, and to a lesser extent, for newspapers. Digital printing is increasingly used for printing jobs previously done with offset, flexo, or screen printing. In the short term, in small format (A3) printing, digital printing is taking over from offset for both color and B&W printing. Print shops and copy stores are digitally printing on printing machines they receive from vendors like Xerox, HP, Canon, and Konica Minolta. Labels are also increasingly being digitally printed. Billboard and point-of-sale or point-of-purchase jobs are done by wide-format inkjet devices. There are various small-format printers used to print on phone cases, mugs, and other products. In book printing, publishing companies are increasingly relying on on-demand printing. The Espresso Book Machine shown below is very suitable for this job. Dye sublimation is a printing process that uses heat to transfer a dye onto a substrate. Dye sublimation printers are commonly used for textile printing, proofing, and photo printing. Some printers can print on various materials such as paper, plastic, and fabric. Direct thermal printing applies heat to paper to change a special coating color. This process is used in receipt printers and also to add marks like serial numbers to products. For this, a transparent ink is used that changes color when heat is applied by a laser.