Glass Painting Machine Popular Products

What is a Glass Painting Machine?

Glass painting machines are a type of equipment used for coloring or adding patterns to glass products or surfaces. The glass machine is typically used to decorate or customize glass items or panels. Glass painting machines can work with various methods that apply different colors of paint or create patterns on glass surfaces.

Silkscreen Printing: In this method, paint is applied to glass surfaces using a special silkscreen stencil. The stencil creates the desired pattern and paint is pressed onto specific areas of the stencil. The glass product is then left to dry.

Automatic Spraying: In this method, paint is sprayed onto glass surfaces. Automatic spraying machines help achieve specific patterns or colors by applying paint precisely.

Brushing or Touching: Some glass painting machines apply paint to glass manually using a brush or similar tool. This method allows for more handmade and unique designs.

Serigraphy Glass Printing Machines: These machines print on glass surfaces using special silkscreen stencils. The stencils create special patterns or designs and allow paint to be applied to specific areas.

Digital Glass Printing Machines: Machines that print colored images or patterns on glass surfaces using digital printing technology. These machines can easily apply complex and multicolored designs.

Glass Silkscreen Drying Ovens: There are ovens used to speed up the drying of paints applied with silkscreen on glass. After painting, the glasses are heated and dried in these ovens.

UV Printing Machines: UV printing machines create patterns or prints on glass surfaces using special UV inks. These inks dry quickly under UV light, providing fast drying times and durable results.

Glass Interior Printing Machines: These machines create patterns or prints inside the glass. This provides a more protected result compared to prints applied to the external surface of the glass.

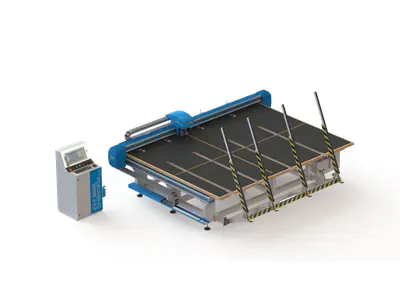

Automatic Glass Painting Machines: These are machines that can be integrated into automation for the mass production of glass products. They speed up the painting processes and improve quality.

Glass Decoration Machines: Used to add patterns, logos, or decorative elements to glass items or furniture. They are preferred in businesses such as restaurants, hotels, and retail stores.

Glass painting and printing machines are widely used in the glass industry, interior design, advertising, gift production, and many other sectors. The choice of machine can vary depending on your production needs, budget, and design requirements. Glass painting machines are used to decorate or personalize various glass products (vases, glasses, windows, mirrors, etc.) made of glass. With some advanced machines, how glass painting is done, how it benefits, can have different features according to various needs and design preferences in the glass industry.

Types of Glass Painting Machines

Glass painting machines come in different types to meet various needs and applications.

Silkscreen Machines: Silkscreen glass painting machines apply paint to glass surfaces using special silkscreen stencils. These machines are suitable for mass production of a large number of glass products and provide high-quality results.

Spraying Machines: Glass spraying machines perform the process of painting glass surfaces by spraying paint. These machines are ideal for fast production and can often be integrated with automation.

Hand Painting Equipment: Hand painting or brushing may be required for some glass painting processes. Such equipment is useful for artists or businesses producing handmade glass products.

UV Painting Machines: UV glass painting machines apply designs or colors to glass using special paints that dry under UV light. They provide quick drying times and help achieve high-quality results.

Electronic Control Machines: Some modern glass painting machines are equipped with electronic control systems. These systems assist in adjusting and repeating patterns or colors precisely.

Pattern Transfer Machines: These machines are used to transfer patterns or prints onto glass surfaces. They are often used to apply different patterns on glass.

Thermal Glass Painting Machines: Thermal glass painting machines are used to apply paint to glass surfaces with temperature control. This method allows colors to penetrate the glass surface, resulting in durable results.

Airbrush Machines: Machines that work with airbrushes use air pressure to control the spraying process. This helps process fine details and create customized designs.

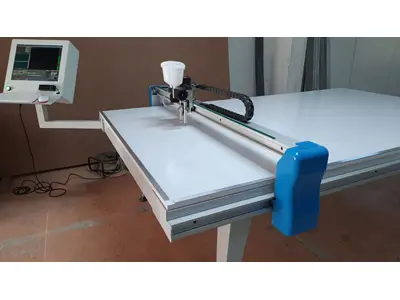

Pattern Drawing Robots: Robots can precisely draw specific patterns or designs on glass surfaces. These machines can be used to decorate or personalize large glass panels.

Glass Ovens: Glass painting processes are often fixed by baking. Glass ovens ensure that the paint adheres well to the glass surface, resulting in durable results.

Glass Painting Materials: There are different types of paints and colors available for glass painting. Paint, brushes, stencils, and other materials suitable for the glass painting process are used during the glass painting process.

CNC glass painting machine is a type of CNC (Computer Numerical Control) equipment that helps automate the application of colors or designs on glass surfaces. This type of CNC paint machine automates the customization and decoration of glass products using computer programs and precise motion control systems.

3D Glass Painting Machines: These machines help paint or design glass surfaces with three-dimensional effects. They are particularly useful for artworks or special glass products.

Glass painting machines are commonly used in glass art, glass industry, and businesses producing decorative glass products. The type of machine to be chosen can vary depending on production needs, glass processing machines, budget, and desired results.

Glass Painting Machine Prices

Glass painting machine prices can vary depending on various factors. These factors include the type of machine, painting capacity, automation level, brand, and manufacturer. Different types of glass painting can be done in a small or large glass painting machine within the machine. Also, considering whether to buy a new or used machine can make a big difference in price. To provide a general overview, basic glass painting and printing machine prices can generally range as follows:

Manual painting brushes and similar equipment in Glass Painting Machines are generally affordable and can start from a few hundred dollars. Silkscreen machines can come with prices starting from thousands of dollars depending on custom design and capacity. Digital printing machines can be more costly, with prices ranging up to tens of thousands of dollars. UV printing machines can vary significantly in price based on painting quality and capacity. The prices of these machines can start from tens of thousands of dollars. Automatic machines in glass processing facilities offer automated machines that provide complex designs and high speeds, hence generally have higher costs. The prices of such machines can exceed tens of thousands of dollars.

Prices can vary from manufacturer to manufacturer and based on machine features. Additionally, second-hand or used glass painting machines may be more budget-friendly, but in this case, the condition and performance of the machine should be carefully examined.

Before purchasing a glass painting machine, you can get price information from many different options and manufacturers considering your needs, budget, and projects from the companies manufacturing, marketing, and selling at makinaturkiye.com. Also, factors such as maintenance requirements and operating costs of the machine should be taken into account.