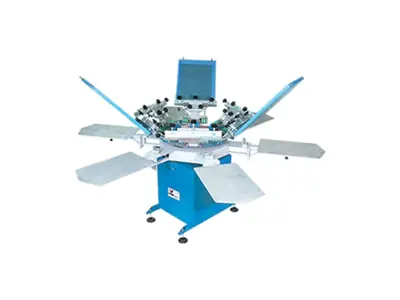

If you are manufacturing a fabric or printed product and looking for a machine that will make your job easier, faster, and also provide high-quality printing, then this octopus printing machine is the one you need. The octopus printing machine, as the name suggests, is a machine with multiple arms that work synchronously with each other to place the product to be printed on the printing table on the machine, and through the ink reservoir and mold on the octopus arms working on sliders, the paint process on the workpiece is done by the machine.

In many garment factories or garment workshops, octopus printing machines come in various options such as single octopus printing machine, quad octopus printing machine, hexa octopus printing machine, octet octopus printing machine, decimal octopus printing machine, duodenary octopus printing machine, and quaternary octopus printing machine, and they all have the common feature of being able to perform multi-colored printing operations quickly by changing molds. Rotary printing machines should be used together with auxiliary machines, including octopus printing machines, when we make a generalization. These include dryers, which are manual dryers or conveyor intermediate drying machines used to dry the painted workpiece, mold removal equipment, and drying cabinets.