Pallet Disassembling Machine Popular Products

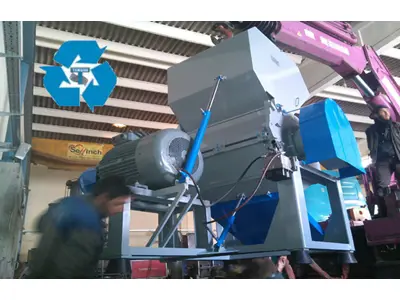

What is a Pallet Shredder Machine?

A pallet shredder machine is an industrial machine used to separate used or waste pallets into smaller pieces. These types of machines are commonly used in recycling facilities, wood processing plants, or logistics centers. A pallet shredder machine allows pallets to be integrated into recycling or waste management processes by separating them into smaller pieces, thus transforming unusable parts of pallets into reusable materials.

The machine typically cuts, shreds, or disassembles pallets using a saw system or similar cutting elements. These pieces can then be repurposed for different purposes, such as wood chip production, fuel production, or furniture production. The machine can cut and separate all types of pallets with no regard for nail type or pallet condition without causing fainting issues. It absorbs vibration on a large scale using car tires, extending the saw's lifespan, reducing saw costs, and enabling operators to work more efficiently.

The rubber system can be quickly replaced with a jack, making saw changes fast and easy. The machine's chassis behind the saw is easily adjustable by the operator using a rack-pinion system according to the pallet size, reducing the operator's energy consumption. Pallet shredding machines are designed to process pallets efficiently and quickly, contributing to waste management, recycling, and material recovery processes.

Single Shaft Industrial pallet shredders can greatly reduce pallet disposal costs by shredding pallets to reduce their volume. These machines reduce the number of weekly waste containers, eliminate unsightly and unhygienic pallets, and can quickly cover their own costs.

Pallet shredders are designed to be simple and easy to use. They perform high torque shredding at low speeds. These machines are designed in sizes suitable for small and large-scale operations. They are the most economical solution for reducing unwanted pallets. The shredders work by shredding pallets, nails, and other elements. Their heavy structure allows them to easily process large and heavy pallets.

Industries Using Pallet Shredding Machines

Pallet shredding machines can be used in various industries. The choice of industry may vary depending on the characteristics of your business, goals, and market needs. Some industries that require easy pallet shredding for reducing workloads and avoiding unnecessary expenses include:

- Recycling and Waste Management: Pallet shredding machines make used pallets recyclable by breaking them down into smaller pieces of wood. This is a common practice in recycling and waste management facilities.

- Wood Processing and Chip Production: Shredded pallet materials can be used for chip production. These chips are used in furniture production, plywood production, and other wood processing tasks.

- Energy Production: Shredded pallet materials can be used as fuel for biomass energy production. This fuel can be used in power plants and heating systems.

- Construction and Building Materials: Pallet shredding machines can also be used in the construction sector. Shredded wood materials can be used in the production of various building materials.

- Furniture Production: In the furniture production sector, shredded pallet materials can be used in furniture making. These materials can be used for making various parts in furniture production.

- Logistics and Storage: Shredding and recycling used or damaged pallets in the logistics and storage sector can reduce the cost of purchasing new pallets.

- Packaging and Shipping: Pallet shredding machines can turn pallets used in packaging and shipping into low-cost materials, making material management more sustainable.

- Reuse and Repurpose: Pallet shredders are an important tool for businesses looking to repurpose and reuse useful parts of pallets for different purposes.

Each of these industries may vary depending on your business expertise, market research, and goals. Good market research and business planning will help you determine which industry you could be more successful in. You can use pallet shredding machines for different purposes and benefit from the efficiency and recycling advantages these machines provide.

Types of Pallet Shredding Machines

Pallet shredding machines come in various types to suit different needs and usage scenarios. Pallet shredding machines may be offered with different specifications by different manufacturers. For example, if you are looking for a machine that can shred 30 pallets per hour, you need to pay attention to the machine's features. However, some basic features that pallet shredding machines may have include:

- Powerful Motor: High-powered motors are necessary to effectively shred pallets. Motor power affects cutting capacity and efficiency.

- Cutting Tools: The type and quality of cutting tools used to shred pallets are important. These tools are typically blades or saws.

- Automation System: Automatic feeding and transport systems can make the process easier and reduce operator intervention.

- Nail and Metal Detection: Detection systems identify nails, screws, and metal pieces in pallets to prevent damage to the cutting tool.

- Cutting Speed and Torque: Low-speed high-torque cutting provides effective shredding. It is important for safely and efficiently processing pallet material.

- Operating Platform: The machine features a control panel or platform for the operator to control the machine and monitor the process.

- Waste Management: Shredded pallet materials are reduced to smaller sizes and prepared for recycling or energy production.

- Capacity and Size: The machine's processing capacity should be suitable for pallet sizes and workloads. Additionally, the machine's physical dimensions are important for ease of installation and use.

- Safety Features: Safety precautions on machines are necessary to ensure the operator's safety. Features like detection systems, emergency stop buttons, and protective covers enhance safety.

- Maintenance Convenience: The machine should be easy to maintain and clean. Features like replaceable cutting tools, easily accessible parts, and ease of cleaning are important.

- Manufacturer Brand and Guarantee: Choosing a reliable manufacturer brand can provide you with quality products and support. Additionally, the machine's warranty period and technical support are important.

- When selecting a pallet shredding machine, it is important to choose a machine that meets the needs of your business, processing volume, and budget.

- Hand Saw Type Machines: Hand saw type pallet shredding machines are used for smaller-scale operations. The operator manually cuts boards with a saw-like cutting tool. These machines generally work at lower power and with less automation.

- Single Shaft Pallet Shredding Machines: Machines with a single cutting shaft are typically used for smaller-scale operations. They offer a more compact structure and ease of use.

- Double Shaft Pallet Shredding Machines: These machines have two cutting shafts, providing more torque and cutting capacity. They ensure effective shredding of strong materials and large pallets.

- Tabletop Machines: These machines use a fixed cutting tool on a tabletop. The operator places the pallet on the cutting tool and cuts the boards underneath the tool. Tabletop machines provide a more organized cutting process and are generally suitable for small businesses or workshops.

- Conveyor Belt Machines: These machines automatically place pallets on a conveyor belt for cutting. With an automatic feeding system, the processing speed increases and operator intervention decreases. These machines are generally preferred in medium-scale operations.

- Manual Control and Automatic Pallet Shredding Machines: In addition to machines that allow operators to control the process manually, there are models that operate automatically and minimize operator intervention.

- Industrial Pallet Shredding Machines: Used in large facilities or recycling centers, these machines are equipped with high-powered motors and automation features. Models with multiple cutting tools and automatic transport systems are available.

- Mobile Pallet Shredding Machines: Can be used in different work sites due to their portable structures. They are ideal for quickly processing waste pallets in the field.

- Odd-shaped Pallet Shredding Machines: Cutting tools shred pallets into cube-like shapes. These machines allow the use of wood material for different purposes.

- High-Capacity Pallet Shredding Machines: Designed for large-scale industrial operations. They can effectively process large volumes of pallets with high-powered motors and wide feeding capacity.

- Impact Pallet Shredding Machines: Cutting tools shred pallets with high-speed rotating movements. They provide high efficiency.

- Multi-Point Cutting Machines: These machines have multiple cutting points for simultaneous cutting of multiple boards. This can increase processing speed.

Fast pallet shredding machines are industrial machines designed to efficiently and quickly shred used or waste pallets into pieces. These machines are commonly used in large facilities, fast pallet shredding machines, recycling centers, or wood processing plants. Various design features and technologies are used to increase processing speed and efficiency.

When selecting a pallet shredding machine, it is important to choose one that suits the needs, processing volume, and budget of your business. Safety and user training should also not be overlooked.

Pallet Shredding Machine Prices

Pallet shredding machine prices can vary greatly depending on several factors. These factors include machine type, power, cutting capacity, level of automation, manufacturer brand, and the technologies and energy used. Additionally, geographical location, market conditions, and exchange rates can also affect prices.

Generally, prices for basic tabletop or hand saw type pallet shredding machines with less automation can be lower, while industrial and high-capacity machines may have higher price ranges.

As an approximate estimate, the price of a basic tabletop or hand saw type pallet shredding machine varies. For larger capacity or conveyor belt machines with automation, you can contact manufacturers or sellers on our portal to get information. You can buy a second-hand pallet shredding machine from sellers who sell used pallet shredding machines.

However, prices can vary depending on market and technological developments, so to get current and accurate prices, you can contact manufacturers or sellers of pallet shredding machines for sale through our portal. You can also learn about machine features, warranty, technical support, and training.