Cooling Air Dryer Popular Products

The places where air dryers are placed should be cool places. Mechanically operated air dryers should not be placed next to machines such as ovens or steam boilers, there should be quite a distance between them. Because these machines emit heat into the environment. This situation can disrupt the operation of air-cooled machines by causing damage. If suitable conditions for placement cannot be provided, the environment should be ventilated frequently and a suitable environment should be provided for the air dryer. Air dryers generally have a structure consisting of small fins formed on the heat transfer surfaces where steam passes. When air dryers get dirty, they cannot be cleaned. The prices of air dryers vary according to the capacity dimensions of the product. Air dryers have been minimized by production companies with special materials and products. The weight center is also calculated and made according to the most suitable transportation method.

Not every environment needs to use an air dryer. The use of the machine can also vary depending on the compressed air or the process you are performing. For example, air dryers must be used in all places where pneumatic systems are used. However, in places used only for cleaning purposes, there is no obligation to use it.

What is an Air Dryer Machine and How Does It Work?

In many environments under normal conditions, there are invisible water particles in the air. These are also known as humidity. The air dryer compresses the air it draws in the environment. The compressed air also converts the humidity in it into water. Humidity and water are always present in compressed air. This moisture in the environment and system must be removed. If not removed, the system will lose efficiency. This increases maintenance needs. It can lead to unnecessary expenses such as production loss or maintenance costs.

The air dryer machine is a machine that allows moist air to be dried. A compressed air dryer can be used to minimize the humidity in the system. Compressors send a certain amount of moisture in the air they use as part of their working principle to the system. The transfer of moisture to the system indicates a negative situation for compressed air. This situation arises when the air generator cannot provide sufficient cooling in hot weather. To prevent this, air dryer machines are preferred.

Operation of Air Dryer Machine

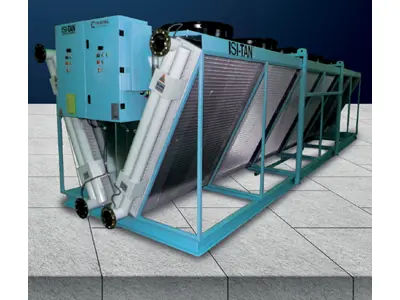

Dry and compressed air is of great importance in some workplaces. Generally, food sector or hospitals are the greatest examples of these. Air dryer machines provide maximum efficiency even in the harshest environmental conditions. Before going to the compressed air line, the compressed air dryer removes the moisture and cools it. The air dryer machine prevents damage to the drying air pressure system and equipment. It is very easy to install and provide compressed air of high reliability and quality. Product performance and machinery used in the product are obtained from well-equipped parts on the market. You can visit makinaturkiye.com for product choices that provide the highest quality, maximum efficiency, and environmentally friendly way.

The drying method of air is determined by the hardware used and the lowest desired ambient temperature. The most commonly used dryer is the refrigerant dryer. Its main feature is to cool the compressed air to remove moisture. As the compressed air passes through the dryer, the compressed air cools, and the water inside the air condenses. It collects in the drainage containers with oil vapors and is automatically expelled outside the system.

Types of Air Dryer Machines

The refrigerant air dryer cools the compressed air through mechanical cooling and circulation, causing the compressed air inside to cool and the water and oil vapor in it to condense. The condensed water and oil are collected at the outlet of the air dryer machine and periodically emptied. In refrigerant air dryers, it cools the compressed air to 2°C. At the same time, refrigerant air dryer machines have a pressure range between 1°C and 4°C.

The evaporators used in high-pressure air dryers provide long life due to their high strength and durability.

The refrigerated air dryer always contains moisture in the air inhaled by the air compressor. The amount of moisture in the air varies according to the condition of the air. Moisture in the air causes many negative effects in compressed air systems. Corrosion of the installation or loss of gauge are examples of these. Clean and dry compressed air will always make your installation work better. The pressure range of refrigerated air dryers is between 2°C and 10°C.

A compressed air dryer turns into a harmful paste when it comes into contact with the dust and lubricating oil added from the ambient air in the inhaled air. This paste damages the machines in the environment. To prevent these damages, a compressed air drying machine can be used. In normal environments, there is a water vapor existing in the ambient air, which also carries moisture. The hotter the air, the more water vapor it carries. If the humidity is not controlled, it causes a lot of problems in the compressed air piping system by liquefying. The compressed air drying machine prevents these negativities.

Why Use an Air Dryer Machine?

Air dryer machines provide protection against water, oil, and dirt. In order to minimize the damage to machine parts against moisture, air dryer machines should be used. The prices of air dryer machines may vary depending on the brand and operating method. To choose the most suitable, quality, reliable, economical, and long-life air dryer machine, you can visit makinaturkiye.com.

Some tools cannot tolerate hot compressed air. Machines in this situation have moisture separators in their bodies. These coolers cool the compressed air, causing a significant portion of the water in it to condense. The water and oil gather in separation containers and are expelled from the machine. Failure to discard it will cause problems in the machine. To prevent these problems, air dryer machines are used. It is possible to get rid of water vapor and all other dirt with the air dryer machine. Of course, it is also very important to select and place the devices correctly according to their purpose.

What Should Be Considered When Choosing an Air Dryer?

There are some situations to be aware of when choosing an air dryer. Firstly, an air dryer machine should be selected that is equivalent to or greater than the compressor capacity. Wanting less or more efficiency does not mean a correct choice is made. However, in such a choice, the user does not have to choose the correct air dryer machine. Because the output temperatures of the produced compressors vary. When buying or using an air drying machine, what is important is whether the air obtained in the environment is clean, oil-free, and dry air or not. Actually, in order to achieve the desired efficiency, the correct air dryer machine must also be chosen. For this reason, attention should be paid to the compressor brand, capacity, and information about the installation when choosing the most correct air dryer machine. One of the most important factors to be considered from the information about the installation is the structure of the material used in the installation and how much water this structure produces. For example, there are differences between a system made with metal pipes and a system made with plastic pipes. Water formation is an important factor in buying an air dryer machine.