Baling Machine Popular Products

What is a Baler Machine?

A baler machine is used in agriculture to compact harvested plants, hay, or straw into tightly packed bales. The baler machine is designed to make agricultural products more suitable for storage, transportation, and processing. It speeds up the baling process and increases efficiency by replacing manual labor. Once baled, the bales can be transferred to a bale collection machine without damage or difficulty.

Baler machines come in different sizes and capacities. Small hand-held machines are used in small farms, while larger baler machines are used in larger agricultural operations or industrial-scale farming activities.

Baler machines are important tools that make it easier to store, transport, and sell agricultural products in a practical way, thus simplifying and enhancing life.

Types of Baler Machines

Baler machines come in various types to cater to different agricultural needs and types of products. There are different types based on usage areas.

- Cylinder Baler Machines: These machines compress harvested plant materials into cylindrical bales. Cylinder baler machines are commonly used in producing round bales. Farmers and large agricultural operations typically use cylinder baler machines.

- Square Baler Machines: Square baler machines produce bales that are compressed into square or rectangular shapes. Square bales are more uniform in shape and easier to stack during storage or transportation. They are generally used for baling products like hay or straw.

- Roll Baler Machines: A roll baler machine produces long cylindrical bales, which are often used as cattle feed. Roll bales take up less space during storage and transportation and are sometimes used with automatic loading systems.

- Automatic Baler Machines: Automatic baler machines are highly efficient machines that automate most of the process. They gather, compress, tie, and discharge bales automatically. Automatic baler machines are suitable for large agricultural operations or industrial use.

- Handheld Baler Machines: These machines are designed for small farms or personal use. Handheld baler machines have smaller sizes and lower production capacities.

- Stationary Baler Machines: Stationary baler machines are generally used in a fixed position and are usually not moved with a tractor. They are suitable for small-scale farming activities.

- Mobile Baler Machines: Mobile baler machines can be transported with tractors or other transport vehicles. Mobile baler machines provide flexibility in use across different field areas.

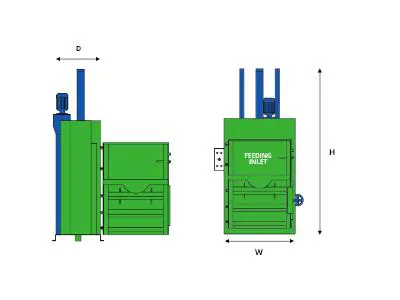

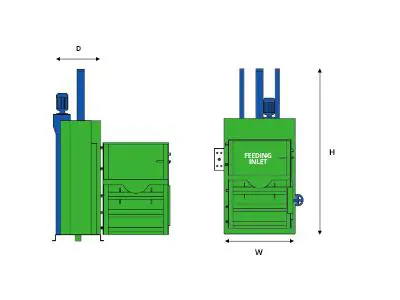

- Vertical Baler Machine: Vertical baler machines are commonly used in waste management and recycling processes. A vertical baler machine is used to reduce waste volume, increase transportation and storage efficiency, facilitate the processing of waste materials, and contribute to recycling processes.

General Uses of Baler Machines

The choice of a baler machine according to different agricultural needs and product types depends on the size of the agricultural operation, product quantity, and transportation/storage requirements. Baler machines are used extensively in the agricultural sector and provide benefits in various areas.

- Baling Hay and Straw: Baler machines compress hay and straw into bales for storage and use as animal feed. These bales are used by livestock farmers to feed animals during winter months.

- Forage and Roughage Production: Baler machines are used to pack forage crops such as corn stalks, clover, and peas or other roughages into bales. They help optimize animal feeding programs.

- Cotton Baling: When cotton is harvested in cotton fields, baler machines are used to compress cotton fibers into cotton bales. These bales are then transported to processing plants or markets.

- Paper and Waste Material Recycling: Baler machines are used to compress recyclable materials, especially paper, cardboard, and plastic, into bales with a waste baling press. This reduces waste volume and lowers transportation and processing costs.

- Industrial Raw Materials: Baler machines compress industrial raw materials or product residues to make them more efficient during transportation and storage. For example, textile production waste or plastic production waste can be baled.

- Transport and Storage of Agricultural Products: Bales make it more convenient to transport and store agricultural products. Tight baling helps prevent damage or spoilage of products.

- Biogas Energy Production: Biomass materials used for plant waste or biogas energy production can be effectively stored and used for energy production by compressing them with baler machines.

- Seedling and Flower Baling: Plant growers or flower cultivators can use baler machines to protect and transport plants.

These are just some of the areas where baler machines are used. In general, baler machines are used to make the storage, transportation, and processing of agricultural products more efficient and effective.

How Does a Baler Machine Work?

The working principle of baler machines involves compressing harvested plants into bales and consists of several stages.

- First, plant materials are collected from the field or harvest area. The plant materials are taken in by the feeding mechanism of the baler machine.

- The collected plant materials are moved to the compression chamber. The compression chamber is designed to compress the plants and turn them into bales.

- The plants carried to the compression chamber undergo the compression process. This process compresses the plants, reduces their volume, and ensures that the bales are sturdy and tight.

- The compressed plant materials are tied by the binding mechanism of the bale loading machine. This mechanism uses twine or wire to hold the bales together. To learn about bale loading machine prices and to purchase one, visit makinaturkiye.com.

- The completed bales are removed from the machine. The bales can then be stored, transported, or processed.

While some types of baler machines automate this process, others may require more human intervention. Automatic baler machines gather, compress, tie, and discharge bales automatically, while simpler or hand-held machines may require some steps to be performed manually. They are designed to produce different types of bales.

While cylinder baler machines produce round bales, square or rectangular baler machines can produce more uniform-shaped bales. Compactifying agricultural products makes the storage and transportation processes easier and reduces the risk of product spoilage or damage while increasing processing efficiency.

Baler Machine Prices

Baler machine prices can vary widely depending on several factors. Prices are determined based on factors such as the type, size, production capacity, features, and brand of the machine. Additionally, choosing between buying a used baler machine or a new baler machine, or opting for a second-hand baler machine, can also make a difference in prices.

-

Machine Type: Baler machines come in different types (cylinder, square, round, etc.). Prices can vary depending on the type.

- Size and Capacity: The size and production capacity of the machine are important factors that influence the price. Machines with larger capacities generally come at higher prices.

- Level of Automation: Automatic or semi-automatic machines typically offer more features and functionality, but this can also increase the price.

- Brand and Quality: Well-known brands often come at higher prices because the quality and performance are usually better.

- New or Used Condition: A second-hand baler machine can generally be purchased at a lower cost, but a new machine may have a longer life span.

- Additional Features: Some machines may have special features, which can affect the price. For example, additional features like automatic lubrication systems, electronic control panels, etc., can incur extra costs.

In general, before buying a simple and smaller hand-held baler machine, it is advisable to determine your needs, get quotes from different suppliers, or find a hand-held baler machine for sale, and research to find the most suitable option. To research baler machine prices, reach out to manufacturers, and ask all your questions, visit makinaturkiye.com.