CNC Wood Processing Machines Popular Products

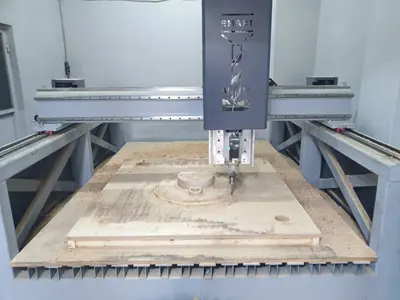

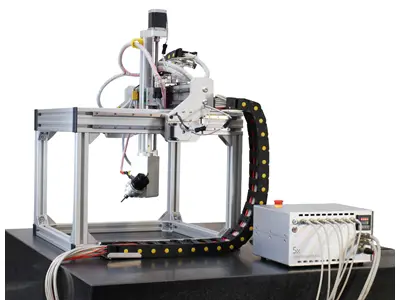

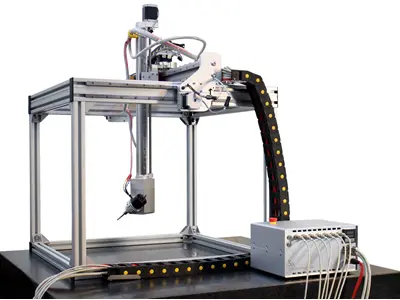

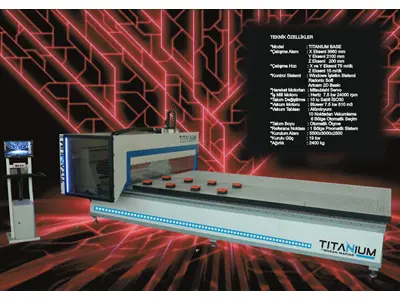

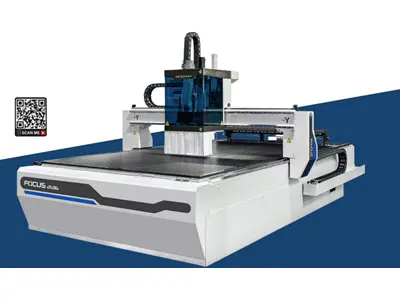

Automatic processing of mechanical operations such as milling, painting, drilling, etc. with the help of computer commands is carried out by CNC woodworking machines. Here are CNC woodworking machines that perform mechanical operations on wood (drilling, milling, painting, etc.). CNC woodworking machines are commonly used in the woodworking industry. 3D scanner, pattern machine, CNC woodworking machines, CNC carving (for wood), and pantograph machine are commonly used machines. They can process a variety of materials from wood to metal. Machines with new and second-hand options are available on the Machine Turkey page. CNC Carving, one of the most commonly used CNC cutting methods, is a method in which a computer-prepared pattern is engraved or cut into a plane according to the given pattern. Companies that perform CNC carving can shape surfaces such as wood, aluminum, plexiglass, and styrofoam. Pricing for CNC carving can vary depending on the nature of the surface where the process will be performed.

\r\n\r\nThe accuracy of the work done with CNC woodworking machines is much higher compared to manual work. Since the machine processes wood with computer commands, there is no need to wait around while the machine is working. CNC woodworking machines automatically process with pre-drilled bands according to a specific standard. With these machines, many tasks are completed within seconds without human intervention. These machines provide advantages in terms of both time and cost. They are used to carve, shape, emboss, and engrave various materials such as wood, MDF, chipboard, composite, plexiglass, derlin, polyurethane, and light metals. They can perform 3D machining. Complex geometric surfaces are easily created (spherical surfaces, sculptures, etc.). They perform tasks with high accuracy. Identical parts can be easily produced. There is no need to wait around while the machine is working. The manufacturing process offers great flexibility.

\r\n\r\nA CNC machining center works on the principle of cutting material with a high-speed rotating cutting edge on a flat surface. The cutting edge is usually diamond and rotates at very high speeds to abrasive the material for cutting. While it can be very precise, the cutting-edge solutions achieved in CNC technologies can offer much more advanced solutions. However, for cutting and shaping materials such as wood that do not have high heat resistance, the physical use of CNC cutting machines may be required. Shaping wood with methods such as oxygen and plasma is quite difficult due to the fire factor.

\r\n\r\nYou can find suitable machines for yourself with high quality and low prices with trust by applying filtering on our page. With the development of technology, the role of CNC routers in our lives has increased significantly. Especially in industrialized societies, their use is increasing. These computer-assisted machines have the ability to move independently along three axes, X, Y, and Z. Therefore, you can process shapes and patterns you design on the computer without design restrictions. In simple terms, these machines automatically perform a task that requires mechanical processing (drilling, milling, painting, etc.) according to commands received from the computer. Furthermore, with the recent technological advancements, more robust and more precise CNC processing models can be produced. You can also easily process many products and save time with this machine. Machines are presented to you on our page with a guarantee. Hundreds of brands and models, instant access to sellers are available here. Both for sale and rental options in the category of CNC Woodworking Machines.

\r\n