APPLICATION AREAS AND ADVANTAGES

Automotive industry White goods industry Lighting industry General machinery manufacturing industry

These are facilities that provide high and equal quality with low labor in situations where there is high capacity and continuous production required. Thanks to automation, chemical values and temperature values can be continuously monitored and controlled.

Due to the way it works, it is more efficient and faster compared to immersion type surface cleaning and processing facilities.

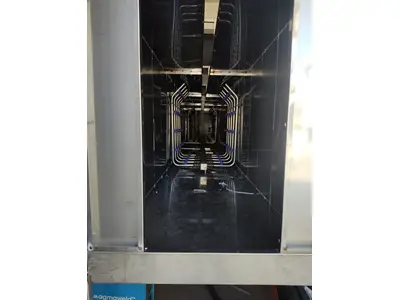

WORKING PRINCIPLE

It is a system that occurs by automatically rinsing the material to be cleaned with water and/or chemicals sprayed at high speed without human assistance. The aim is to clean the existing oil layer on the metal surface and to create a thin film on the metal surface, thereby making the material more suitable for painting and more resistant to external factors.

APPLICATION

Spray Line applications vary according to preferences and necessary resistances for each sector.

As two main applications

– Iron Phosphate surface processing

– Zinc phosphate surface processing can be shown.

In addition to these, applications can also be made solely for cleaning purposes and aimed at removing oil from the material.