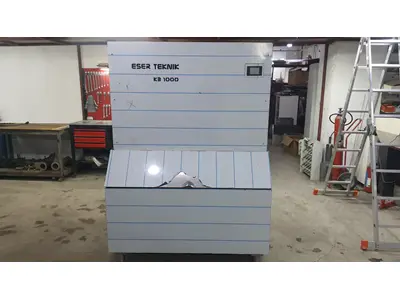

Ice Machines Popular Products

Ice Machine

An ice machine is a device that assists in producing and storing ice. They are commonly found in various places such as restaurants, hotels, bars, markets, and for home use. Ice machines can produce different types of ice such as ice blocks, ice cubes, or ice flakes. The basic operation of ice machines involves freezing water at a specific temperature and cutting or crushing the ice in the desired way. Ice machine is essentially a process of cooling water. In the first step, the water inside the device is cooled to a certain temperature through a cooling system. Then, in the freezing process, the cooled water is directed to an ice-making plate or rotating drum. The water on this surface starts to freeze continuously and forms a layer of ice. The formed ice layer is cut or broken into desired sizes. Depending on the type of ice machine, this process can vary. For example, ice cube machines typically cut ice cubes, while ice flake machines crush the ice. The produced ice is transferred to an inner bin or automatically to an ice storage bin. This ice is stored to be used and distributed according to demand.

How Does an Ice Machine Work

Ice machines work based on thermodynamic principles. Essentially, these machines produce ice by utilizing the transition of water from liquid to solid. Ice production can vary for different types of ice machines, but generally, the steps of the ice machine operation principle are as follows:

The process of water feed begins with feeding the water to a specific point. Water is delivered to the machine where it will be transformed into ice through a water line or water tank.

Water enters the machine and is cooled or frozen there. The cooling or freezing process involves a compressor, cooling coils, and an evaporator. The cooling process keeps the water in liquid form while lowering its temperature to produce fine ice particles. Such ice machines are called shaved ice machines and are used to produce fine icy particles. In the freezing process, the temperature of the water is lowered to even lower levels to solidify the water into solid ice. These types of ice machines are called ice cube machines or mold ice machines and produce large ice cubes or ice blocks.

When the water is cooled or frozen, ice crystals begin to form. These formed crystals continue to grow by adhering to cold surfaces.

Depending on the use of the ice, it may need to be brought to the desired size and shape. This process is carried out using blades or mechanical separators inside the machine. For example, ice cube machines use a blade system to cut large ice blocks into cube-shaped ice pieces.

The ice produced in the desired shape and properties is directed to a storage bin. The bin in the ice machine allows the ice to be stored and awaits readiness for use. The main purpose of this bin is to prevent the ice from melting and maintain its shape.

Finally, ice machines are usually equipped with automatic control systems. These systems monitor and adjust water levels, ice production, and the fullness of the storage bin.

An ice machine operating in this way produces ice by using the freezing or cooling process of water and is designed to produce different types of ice. This principle enables ice to be produced quickly and efficiently and be widely used.

Types of Ice Machines

Ice machines offer different options for commercial and home use. Large capacity ice cube machines are preferred for big establishments like restaurants and hotels, while more compact and portable models can be chosen for home use or small businesses. Also, the shape and size of the ice are important factors; ice cube machines produce large ice cubes, while nugget ice machines can produce more round and nugget-like ice. Ice crushers are used to break large ice blocks into smaller pieces, and they have various applications from cooling drinks to keeping food chilled. When making a choice, types of ice machines will vary depending on your needs and intended use. Below are listed types of ice machines for a more decisive selection:

- Snow ice machine

- Industrial ice machine

- Ice cube machine

- Mold ice machine

- Ice crushing machine

- Ice making machine

- Industrial ice machine

- Dry ice machine

- Sheet ice machine

- Ice cup machine

- Crystal tube ice machine

- Crystal spherical ice machine