Transportation and Conveyor Systems Popular Products

What are Conveyor Belt Systems?

A conveyor belt is a mechanical system used to transport materials quickly and safely from one place to another. It provides great convenience in the transportation of heavy or bulky materials and reduces labor costs. Conveyor belt systems, which minimize risks such as falling or breakage during the transportation of products, are mechanical systems used to facilitate the movement of materials or products from one point to another.

Conveyor systems are commonly encountered in our daily lives. For example, escalators in shopping malls, checkout conveyor belts in supermarkets, and crane palettes are examples of conveyor systems in daily use. These systems are used in a wide range of applications, from industrial production facilities to airports, mining operations, and storage facilities.

Conveyor belt systems are designed to transport materials or products quickly, regularly, and safely from one point to another. Conveyor belt systems are defined as mechanical transport systems used to transport materials or products from one point to another or to facilitate their transportation or processing. These systems are widely used in industrial and commercial applications and can be designed in various ways. These systems transport materials through conveying surfaces placed on them via conveyor belt systems.

Types of Conveyor Belts

Conveyor belts come in a variety of different types to meet various transportation and conveying needs. These systems transport materials through conveying surfaces via conveyor belts.

Rubber Conveyor Belts: Rubber conveyor belts are widely used due to their durability and wide range of applications. They come in hard and soft rubber types and are used to transport materials of various weights.

Loading Belt: A type of conveyor belt system that helps transport materials or products from one place to another, especially used for loading or unloading operations. These belts are commonly used in storage facilities, logistics centers, transportation terminals, and the transportation industry.

PVC Belt Conveyors: PVC conveyor belts are popular due to their chemical resistance and low cost. They are often used in the food industry and light transport applications through PVC belt conveyors.

PU (Polyurethane) Conveyor Belts: PU conveyor belts are known for their durability, abrasion resistance, and cleanability. Therefore, they are frequently preferred in the food processing, packaging, and pharmaceutical industries.

Modular Conveyor Belts: Modular conveyor belts are made up of plastic modules and are often used for transporting products. These belts can be designed in different configurations to fit the surfaces of the products.

Wire Mesh Conveyor Belts: Wire mesh conveyor belts are used in industries that require high-temperature resistance. Made of metal wires, they are particularly preferred in ovens and drying processes.

Belt Conveyor Belts: Belt conveyor belts are commonly used for transporting pallets, boxes, and light materials. The belts on them prevent materials from slipping during transport.

Spiral Conveyor Belts: Spiral conveyor belts are used to transport materials up or down a vertical surface. These belts are often found in industrial ovens and cooling facilities.

Chain Conveyor Belts: Chain conveyor belts are used in places where heavy loads need to be transported and traction force is required. Chain conveyors are commonly seen in mining, automotive production, and large storage facilities.

Vertical Conveyor Belts: These types of conveyor belts are used to transport materials vertically. They are commonly used in warehouse shelves or multi-storey production facilities to transport materials up or down.

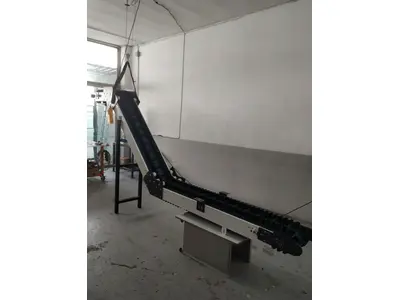

Inclined Conveyor Belts: Inclined conveyor belts are designed to transport materials along an inclined surface. They are used to elevate or lower materials in mining and quarrying operations.

Textured Conveyor Belts: Textured conveyor belts are designed to prevent slippage or hold materials in place. They are especially used on inclined surfaces or when transporting slippery materials.

Magnetic Conveyor Belts: Magnetic conveyor belts are used for transporting iron or steel materials. Magnetic fields are used to automatically separate metal products.

Speed-Control Conveyor Belts: These belts are designed to adjust the speed of transported materials. The ability to change the speed according to the needs of the production line is a great advantage.

Plastic Conveyor Belts: Plastic conveyor belts are suitable for use in hygienic environments such as the food processing industry. They are easy to clean and minimize the risk of materials falling on them.

Coiled Conveyor Belts: These belts are designed to make a curve or turn through rollers or drums. They allow materials to be transported in a specific route and are commonly used in baggage handling systems and distribution centers.

Dual-Layer Conveyor Belts: These types of belts allow products to be transported on both upper and lower layers. They are commonly used in packaging and assembly processes.

Each conveyor belt system is designed to meet specific application requirements and should be selected according to the characteristics of the materials and processing processes. Therefore, a careful evaluation is required when selecting which type of conveyor belt to use.

Applications of Conveyor Belts

The applications of conveyor belts are very wide and they are an important transportation and production tool for many industries and businesses. Conveyor systems are also commonly encountered in our daily lives. For example, escalators in shopping malls, checkout conveyor belts in supermarkets, and crane palettes are examples of conveyor systems in daily use.

Manufacturing and Production: Used in production facilities to transport products from one production line to another, for assembly processes and packaging of products.

Food and Beverage Industry: Used in food processing plants to transport and process materials for washing, cutting, filling, and packaging.

Automotive Industry: Used in automobile production to transport parts between different assembly stations.

Logistics and Storage: Used in large warehouse facilities for transporting products to storage areas, picking operations, and preparing for transportation.

Airports: Used in baggage handling systems at airports to transport baggage to different points in the terminal.

Power Plants: Used in power plants for fuel and material transport operations.

Mining and Quarry: Used in mining operations to transport materials extracted from mines to processing facilities or transportation points.

Agriculture: Used in the agriculture sector for harvesting, transporting, and packaging operations.

Packaging Industry: Used in packaging facilities for the production and packaging of packaging materials.

Paper and Printing: Used in the production and transport of paper products, books, and magazines.

Chemical Industry: Used in chemical plants for mixing, transporting, and packaging chemical products.

Fast Food and Restaurant Chains: Used in fast food restaurants for preparing and delivering orders.

Textile Industry: Used in textile factories for processing fabrics and manufacturing clothing products.

Environment and Recycling: Used in waste management facilities for transporting and sorting recyclable materials.

These are just a few examples of industries where conveyor belts are used. Conveyor belts of different types and characteristics can be designed to suit various industrial applications. Therefore, each sector and business can choose a suitable conveyor belt system.

Conveyor System Prices

The prices of conveyor systems vary widely depending on several factors and have a wide range. In general, before getting a price quote for simple and special conveyors, it is important to determine your needs and specifications, and it will be beneficial to compare offers from different suppliers. You can purchase a conveyor system from companies that market and sell new or used conveyor systems on makinaturkiye.com, and you can consult for technical support if you have any questions.